Czech utility company uses optical gas imaging to check for SF6 leaks

Sulfur hexafluoride (SF6) is often used as an insulating gas in the distribution of high voltage electrical power because it allows substation equipment to be more compact. However, SF6 is a very potent greenhouse gas, so any leaks from the equipment can both endanger the continuity of power distribution and have consequences for the environment. To limit these negative impacts, utility companies can detect SF6 leaks with an optical gas imaging camera such as the FLIR GF306 or FLIR GF77.

One utility company that has embraced the use of optical gas imaging technology is the Prague, Czech Republic, based ČEPS a.s. It is the sole Czech transmission system operator and holds an exclusive license to that effect granted by the Czech Energy Regulatory Offi ce under the Energy Act. The company is responsible for the maintenance and upgrading of 39 substations comprising 68 transformers, which allow electricity to be supplied from the transmission system to the distribution network. Almost all of the circuit breakers, current transformers, voltage transformers and gas insulated substations in the distribution network use SF6 as insulator. This dielectric gas is very effective as an insulator as it helps to prevent or rapidly quench electric discharges, making it the most commonly used insulating gas in high voltage equipment around the world.

“Detecting SF6 leaks in an early stage helps to avoid breakdowns and ensures continuity in the power distribution,” explains Milan Sedláček, head of the High Voltage Maintenance Department at ČEPS a.s.

OPTICAL GAS IMAGING TECHNOLOGY

“We tested an optical gas imaging camera on a current transformer that was leaking SF6 and we immediately realized its potential,” says Sedláček. “We had tried unsuccessfully to detect the leak with other means, but with the optical gas imaging camera we managed to fi nd out where the problem was located. Following this surprisingly successful demonstration we have purchased the camera and we have not regretted that decision. It has proven to be very effective even within a few months of use.”

GAS SNIFFERS VERSUS OGI CAMERAS

As SF6 is colorless, odorless and not flammable, it is nearly impossible to detect with the naked eye. A commonly used tool to detect this invisible gas is the so called ‘sniffer,’ a device which measures the concentration of a certain gas in one single location and generates a concentration reading in parts per million (ppm). Although these tools are very useful, their use is limited, according to Sedláček.

“A sniffer only detects gas leakage in one point. This means that it is very easy to miss a leak. The current transformer we used to test the optical gas imaging camera is a good example. We knew it was leaking, as we needed to top it up with SF6 every six or eight months or so, but we could not locate the leak with sniffers. With the camera we were able to locate the leak very swiftly,” he explains.

FINDING LEAKS IN UNEXPECTED LOCATIONS—FROM A DISTANCE

SF6 leaks in electrical equipment may occur due to installation errors, disturbance during planned maintenance or failure of the sealing parts due to age. The most common leak paths found on electrical distribution equipment are flanges, bushings, bursting discs and valve stems. “As long as leaks are confined to the locations where you expect them sniffers can be very useful, but leaks often occur in unexpected locations,” explains Sedláček.

“In the case of the current transformer we used to test the optical gas imaging camera, the leakage occurred in the material of the current transformer head—not in a location where two parts joined, where you would suspect a leak,” Sedláček continues. “We would never have been able to find the location of the leak with a sniffer. Sniffers just give you a one point measurement, while the optical gas imaging camera gives you an overview of the entire current transformer or other piece of equipment you are inspecting.”

The main advantage of optical gas imaging when compared with other methods is the detection range, according to Sedláček.

“With a sniffer you have to be within just a few millimeters of the leak location to detect the SF6 leak, but we found that the optical gas imaging camera can detect small leaks from six meters, so it can be used safely while the equipment is under charge. This means that no downtime is required for the inspection, which is a huge advantage for us.”

Another advantage is the increased inspection speed. “Using sniffers to find gas leaks is a time consuming exercise. You have to physically hold the sensor next to each likely leak location,” says Sedláček. ”With the optical gas imaging camera you can scan an entire piece of equipment in one go. And since it has the dimensions and weight similar to a regular video camera, it’s easy to use in the field.”

HIGH SENSITIVITY MODE

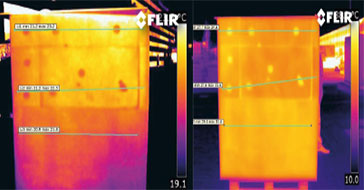

One special camera feature that Sedláček uses often is High Sensitivity Mode (HSM): an image subtraction video processing technique that effectively enhances the thermal sensitivity of the camera.

HSM subtracts a percentage of individual pixel signals from frames in the video stream from the subsequent frames. This enhances the differences between frames, which make leaks stand out more clearly in the resulting video.

AN EXCELLENT INVESTMENT

According to Sedláček, the choice to invest in an optical gas imaging camera was a good one. “It allows us to find and therefore fix gas leaks swiftly, which saves money that would otherwise be spent on topping up with SF6, and does so without requiring downtime while we find the leaks,” he says.